LOL! It seems I misunderstood "slip". Slip connections won't fit into each other, but they do fit into pipes. That helps. And it means I don't have to worry about "hubs"!

But still, I went back to Home Depot and Lowe's and they just don't have complete selections in any size. I am going to a plumbing specialist store tomorrow. The Home Depot Plumbing Manager suggested one locally. I certainly didn't know about the place.

The local HD and Lowe's have basic parts and I wrote down the prices of the parts they do stock (and to indicate what parts they stock). But I'll be fair about it, if the specialty plumbing store offers competitive prices (within 10% of the HD and Lowe's cost) for the basic parts, I will reward them for the selection by buying all parts there.

Wow, this project is taking so much more time for the design and supply, it is weird. I normally work in wood, so the design is the hard part and the supplies are easy!

I can't wait to get this one done because the parts are so annoying to obtain!

Tuesday, September 22, 2009

Sunday, September 20, 2009

No Project Day

Well, maybe call it "Project Relax". I simply had a good relaxing day today.

First, I went fishing with my best friend Jeffrey. On the way to the fishing place, we stopped at a farmers market. There is lots of crap merchandise there, but still some Amish stands. We bought pickles and relishes from them, and we found a small basket of tomatoes to split between us. There are a few stands with tools and we saw some very strange ones. I wish I had remembered to bring my camera. Some tools were really THAT weird.

We got to the "lake" (a reservoir actually - no one outside of Maryland would call it a lake). Maryland is one of the few states that actually has no natural lakes. But we like to fish there.

We were out on the water at 4 pm. Fishing 10 minutes later. We were using only top water flies and bass bugs. The wind was light, the water was still, the temp was 75 degrees F, the light was partly cloudy... A perfect day to be out fishing. We didn't catch a thing (the previous time, we caught a bass and 3 panfish, so there ARE fish there). But we had strikes and nibbles, so there was some excitement.

Fly fishing for bass is not productive, but we enjoyed it. The lake (it is actually also a State Park) closes at sunset, so we were on our way home after only 3 hours.

As we returned home, we stopped at Home Depot (a big box hardware store if you don't know of it) and looked for some stuff. Jeffrey wanted special cleaning product (which we didn't find), but he found knee pads. I found some neoprene gloves and nylon strap tie-downs for the boat. My old ones weren't holding any more.

After Jeffrey left for home, I made a great dinner. Filet Mignon, baked potato, steamed broccoli, and tomato salad. With wine (Zinfandel)...

Watched some great TV afterward, (Miracle Planet for 3 hours, and finally my favorite animation - Kim Possible - at 1:30 am). Next time, back to projects! I finally cleared out another framed garden box a yesterday! No more weeds, poison ivy, or day lilies left there! And it took an hour to finally dig out the sapling that was deep in that bed. I had to dig down 2 feet in a 2 ft circle to finally get it up. But it was worth the effort!

More about that next time...

First, I went fishing with my best friend Jeffrey. On the way to the fishing place, we stopped at a farmers market. There is lots of crap merchandise there, but still some Amish stands. We bought pickles and relishes from them, and we found a small basket of tomatoes to split between us. There are a few stands with tools and we saw some very strange ones. I wish I had remembered to bring my camera. Some tools were really THAT weird.

We got to the "lake" (a reservoir actually - no one outside of Maryland would call it a lake). Maryland is one of the few states that actually has no natural lakes. But we like to fish there.

We were out on the water at 4 pm. Fishing 10 minutes later. We were using only top water flies and bass bugs. The wind was light, the water was still, the temp was 75 degrees F, the light was partly cloudy... A perfect day to be out fishing. We didn't catch a thing (the previous time, we caught a bass and 3 panfish, so there ARE fish there). But we had strikes and nibbles, so there was some excitement.

Fly fishing for bass is not productive, but we enjoyed it. The lake (it is actually also a State Park) closes at sunset, so we were on our way home after only 3 hours.

As we returned home, we stopped at Home Depot (a big box hardware store if you don't know of it) and looked for some stuff. Jeffrey wanted special cleaning product (which we didn't find), but he found knee pads. I found some neoprene gloves and nylon strap tie-downs for the boat. My old ones weren't holding any more.

After Jeffrey left for home, I made a great dinner. Filet Mignon, baked potato, steamed broccoli, and tomato salad. With wine (Zinfandel)...

Watched some great TV afterward, (Miracle Planet for 3 hours, and finally my favorite animation - Kim Possible - at 1:30 am). Next time, back to projects! I finally cleared out another framed garden box a yesterday! No more weeds, poison ivy, or day lilies left there! And it took an hour to finally dig out the sapling that was deep in that bed. I had to dig down 2 feet in a 2 ft circle to finally get it up. But it was worth the effort!

More about that next time...

Wednesday, September 16, 2009

Boat Canopy

I am so tired of buying $200 boat covers that pool water no matter how tight I tie them, rip at the corners and only last 2 years anyway! So, I got it in my mind to simply build a tentlike cover of standard black plastic sheet on a PVC pipe frame that could just be slid over the boat like a movable carport. I have spent 4 days learning all sorts of things about PVC fittings and is is very complicated. I found sites that had designs for structures, I found sites that sold connectors, and I found sites that sold kits.

Nowhere did I find a site that actually explained what all the fitting choices meant! There are "slip fittings", "hub fittings", "fipt fittings", "sanitary fittings", "street fittings", "furniture grade", "utility grade", "gray", "white", schedule 40", schedule 80", etc, etc, etc.

But I did figure it all out eventually. Indeed, I now know more about PVC pipe fittings than I ever wanted to! Add in the fact that the manufacturers don't want to sell to individuals and the local retailers carry limited selections, and it gets really hard to design what you want.

Just as examples (as best I have figured it out): "Slip" means the end fits inside a hub. "Hub" means there is a larger flange for a slip. "fipt" means that the pipe fitting screws on. "Sanitary fitting" means that the angles go out in a curve. "Schedule" means the amount of pressure the pipes can withstand. "Gray" is more UV resistant than "white". "Street" means that one end has a hub and the other end is a slip. Arggh!

Building a box frame from PVC pipe is not tricky or expensive. Its the FITTINGS and COUPLINGS of any form that deviates from that that are. I designed a first one easily. All I needed were some "4 way 60 degree angles". But no one makes those.

And even when I figured out a design that used standard manufacturer fittings, I discovered that no local stores sold all of them (individually or collectively). Some manufacturers will sell individual fittings "by the box" to individuals. Great, I need 3 on something, and the box holds 20!

As long as I am ranting on this, I will complain about local "big box" retailer websites. They are totally unorganized. You would think they would list their PVC fittings either by pipe size (1 inch, 2 inch) or by type (90 degree elbows, tee fittings, etc). No, they are totally random. You have to search through hundreds of items to find the one you want. And they don't list half the fittings that I know are in the store! That's BAD website organization...

The "kit" sellers are the worst. They offer plans for various constructions, but mention that you have to buy all the pipe separately. In other words, all they are selling are the connectors. And they get 3 times the price for those. LOL! Its like finding a shed "kit" and discovering that all they are selling you is a design and nails...

I'll work the design out tomorrow with what is available locally retail...

Nowhere did I find a site that actually explained what all the fitting choices meant! There are "slip fittings", "hub fittings", "fipt fittings", "sanitary fittings", "street fittings", "furniture grade", "utility grade", "gray", "white", schedule 40", schedule 80", etc, etc, etc.

But I did figure it all out eventually. Indeed, I now know more about PVC pipe fittings than I ever wanted to! Add in the fact that the manufacturers don't want to sell to individuals and the local retailers carry limited selections, and it gets really hard to design what you want.

Just as examples (as best I have figured it out): "Slip" means the end fits inside a hub. "Hub" means there is a larger flange for a slip. "fipt" means that the pipe fitting screws on. "Sanitary fitting" means that the angles go out in a curve. "Schedule" means the amount of pressure the pipes can withstand. "Gray" is more UV resistant than "white". "Street" means that one end has a hub and the other end is a slip. Arggh!

Building a box frame from PVC pipe is not tricky or expensive. Its the FITTINGS and COUPLINGS of any form that deviates from that that are. I designed a first one easily. All I needed were some "4 way 60 degree angles". But no one makes those.

And even when I figured out a design that used standard manufacturer fittings, I discovered that no local stores sold all of them (individually or collectively). Some manufacturers will sell individual fittings "by the box" to individuals. Great, I need 3 on something, and the box holds 20!

As long as I am ranting on this, I will complain about local "big box" retailer websites. They are totally unorganized. You would think they would list their PVC fittings either by pipe size (1 inch, 2 inch) or by type (90 degree elbows, tee fittings, etc). No, they are totally random. You have to search through hundreds of items to find the one you want. And they don't list half the fittings that I know are in the store! That's BAD website organization...

The "kit" sellers are the worst. They offer plans for various constructions, but mention that you have to buy all the pipe separately. In other words, all they are selling are the connectors. And they get 3 times the price for those. LOL! Its like finding a shed "kit" and discovering that all they are selling you is a design and nails...

I'll work the design out tomorrow with what is available locally retail...

Saturday, September 12, 2009

Fishing Rod Rack Project, Completed

I decided to give the rod rack 2 coats of polyurathane. I couldn't do all surfaces each day, so it took 4 days. It's not that it will get much wear and tear, but in the garage it will be exposed to a lot of humidity changes and there isn't anything in the construction that will allow much natural warp shifting.

So here are the final pictures:

Construction Notes: If I had it to do over again, I would have made the 3/4 holes on the top shelf smaller. The opening only needs to be large enough to accept the upper part of the rod. Also, I would make the base holes a bit larger (or at a slight angle). A couple of the base holes were a bit tight.

Fishing Equipment Notes: Anyone looking at the actual rods will notice I have 3 bait-casting rods, 4 spin-casting rods, and 3 fly-casting rods. From the left, the first 3 are for casting baits and large weights into tidal waters, the second 3 are for casting different weight lures in freshwater, and the last 3 are fly rods. 1 of those is a short rod for barrel loop casts in shrubby conditions, 1 is for for casting heavy bass flies and popping bugs, and the one in the cover is my "good real fly rod" for trout. The one spinning rod without a reel (7th from left) is just kind of lonely and waiting for a new reel. The short stubby rod (8th from left) is a "Chesapeake Bay" rod for dropping bait from a boat straight down. I've never caught a fish with it, but I keep it around just in case it is "the right one for some trip". LOL!

If anyone has a question about the construction (or anything else), just leave a comment...

Next project: Movable PVC frame tent for the boat.

So here are the final pictures:

Construction Notes: If I had it to do over again, I would have made the 3/4 holes on the top shelf smaller. The opening only needs to be large enough to accept the upper part of the rod. Also, I would make the base holes a bit larger (or at a slight angle). A couple of the base holes were a bit tight.

Fishing Equipment Notes: Anyone looking at the actual rods will notice I have 3 bait-casting rods, 4 spin-casting rods, and 3 fly-casting rods. From the left, the first 3 are for casting baits and large weights into tidal waters, the second 3 are for casting different weight lures in freshwater, and the last 3 are fly rods. 1 of those is a short rod for barrel loop casts in shrubby conditions, 1 is for for casting heavy bass flies and popping bugs, and the one in the cover is my "good real fly rod" for trout. The one spinning rod without a reel (7th from left) is just kind of lonely and waiting for a new reel. The short stubby rod (8th from left) is a "Chesapeake Bay" rod for dropping bait from a boat straight down. I've never caught a fish with it, but I keep it around just in case it is "the right one for some trip". LOL!

If anyone has a question about the construction (or anything else), just leave a comment...

Next project: Movable PVC frame tent for the boat.

Tuesday, September 8, 2009

Fishing Rod Rack Project, Part 6

I took a few days off from the project (fishing, errands, shopping, TV) but got back to it yesterday. It was "glue and screw" time. I took the time to very carefully align all the corners square and flush.

Since I was using mostly 1 x 4" boards and had many places where I was screwing through the wide edge into endgrain, I made a small drilling jig. Nothing fancy, just a piece of scrap from 1 board. I drilled pilot holes centered halfway of the thickness and set 3/4" from the ends. You can see it in the 1st picture (where I was using it as a clamping block). It really made it easy to drill pilot holes evenly spaced, straight, and right in the center of the boards.

I did half of the basic frame yesterday and let it dry overnight, using a framing square to keep it, well, "square".

Today, I glued and screwed the other half, plus attached the 2 cross braces. When that was done, I prepared to cut (to fit) and attach the 2 vertical braces.

OOPS! I had estimated the 2 pieces to be 23" (and had a 46 1/2" board for the purpose. Guess what? The space to be braced was actually 23 1/2" on each side. I was 1/2" short. I HATE "nominal sizes"! Why can't a 1 x 4" board actually be 1 x 4"?

Fortunately, with all the corners being connected in 3 directions, and glued and screwed on all the edges, it was solid as a rock. So here it is, ready to be polyurathaned tomorrow.

I'll post the "finished" picture when the polyurathane is dry and I have the rack in place with the rods on it...

Since I was using mostly 1 x 4" boards and had many places where I was screwing through the wide edge into endgrain, I made a small drilling jig. Nothing fancy, just a piece of scrap from 1 board. I drilled pilot holes centered halfway of the thickness and set 3/4" from the ends. You can see it in the 1st picture (where I was using it as a clamping block). It really made it easy to drill pilot holes evenly spaced, straight, and right in the center of the boards.

I did half of the basic frame yesterday and let it dry overnight, using a framing square to keep it, well, "square".

Today, I glued and screwed the other half, plus attached the 2 cross braces. When that was done, I prepared to cut (to fit) and attach the 2 vertical braces.

OOPS! I had estimated the 2 pieces to be 23" (and had a 46 1/2" board for the purpose. Guess what? The space to be braced was actually 23 1/2" on each side. I was 1/2" short. I HATE "nominal sizes"! Why can't a 1 x 4" board actually be 1 x 4"?

Fortunately, with all the corners being connected in 3 directions, and glued and screwed on all the edges, it was solid as a rock. So here it is, ready to be polyurathaned tomorrow.

I'll post the "finished" picture when the polyurathane is dry and I have the rack in place with the rods on it...

Thursday, September 3, 2009

Fishing Rod Rack Project, Part 5

Yee Hah! I got half the sides stained early today and did the other sides stained this evening (fruitwood stain). I have to say that brushing on stain with scraps of old white tee shirts works great! It goes on so smooth and evenly. I wear cheap disposable latex gloves, so there isn't even any stain on my skin.

I did one full side, one long edge, and one short edge on each board this morning, and all the other edges this evening. I'll be putting on at least one coat of polyurathane tomorrow. Might do 2 coats.

I did one full side, one long edge, and one short edge on each board this morning, and all the other edges this evening. I'll be putting on at least one coat of polyurathane tomorrow. Might do 2 coats.

Tuesday, September 1, 2009

Fishing Rod Rack Project, Part 4

OK, today I remade the rod shelf. First, I clamped it to the base and transferred the centerpoints with a square.

Drilled the slots on the upper shelf, and set it back on the base to check for errors.

It all looks good. I had to eyeball it a little, even with the square. But they all matched up within 1/8", so that's fine.

After I was satisfied that almost all the cutting was done ((2 side pieces need to be fitted into place at the end, I gave all the pieces a thorough sanding. The boards were quite smooth, but as I learned from a previous project, there is a slight film that makes for uneven staining. I went to a 150 grit. With the random orbital sander, that does a nice job for a garage rack. If it was for in-the-house furniture, I would go to 240 and maybe even 320. But there is a limit to how smooth you can sand softwood anyway.

Tomorrow, I'll dry-fit the pieces together, drill pilot screw holes, and tape the areas to be left unstained for glueup. Then, stain the pieces. Next day, I'll give it 1 coat of polyurathene. After that, it's "glue, screw, and done"!

Drilled the slots on the upper shelf, and set it back on the base to check for errors.

It all looks good. I had to eyeball it a little, even with the square. But they all matched up within 1/8", so that's fine.

After I was satisfied that almost all the cutting was done ((2 side pieces need to be fitted into place at the end, I gave all the pieces a thorough sanding. The boards were quite smooth, but as I learned from a previous project, there is a slight film that makes for uneven staining. I went to a 150 grit. With the random orbital sander, that does a nice job for a garage rack. If it was for in-the-house furniture, I would go to 240 and maybe even 320. But there is a limit to how smooth you can sand softwood anyway.

Tomorrow, I'll dry-fit the pieces together, drill pilot screw holes, and tape the areas to be left unstained for glueup. Then, stain the pieces. Next day, I'll give it 1 coat of polyurathene. After that, it's "glue, screw, and done"!

Monday, August 31, 2009

Fishing Rod Rack Project, Part 3

Today, I set about making holes in the base (F) and slots in the upper shelf (E) for the rods to rest in. After 2 hours of careful work, the only thing I can say is *#>&@*

Translated, that means "OOPS". It happens to me in every project. I do something that seems right but that has a flaw and/or I mismeasure something. On this project, I managed to do both at the same time...

The base has holes halfway through for the butt end on the rods. Some are fat, some medium, and some thin. So I decided to drill them to fit. I put paper tape on the base (so I could mark on it) and measured out the centerpoints. Then to be absolutely sure the shelf slots would match the base holes, I put the boards edge to edge and used a square to mark the shelf slots.

I drilled the holes in the base. The forstner bits are great for large flat holes. It looked great! Then I drilled half-holes in the upper shelf.

I was very careful about that. I used a sacrificial board underneath (because they were through-holes) to prevent tearout. I drilled a test hole in a piece of scrap board. I got some tearout anyway. Well that's the bottom side, so I decided to live with it.

That's part of the *#>&@*< feeling. Because of the way I transferred the base centerpoints to the shelf, the bottom of the shelf as I drilled it would actually be the top side when assembled!

So, when I put the cleancut side of the shelf "up", this is what I saw.

When I switched it so the holes matched up, the tearout side was "up".

And then I noticed that one of the shelf holes was 1/4" offset!

ARGGGGH! I am NOT a happy camper right now. Luckily, I have another 4" board. I'll remake the shelf tomorrow. This time, I'll know to put the shelf board ON TOP OF the base, not NEXT TO it when I transfer the centerpoints...

Translated, that means "OOPS". It happens to me in every project. I do something that seems right but that has a flaw and/or I mismeasure something. On this project, I managed to do both at the same time...

The base has holes halfway through for the butt end on the rods. Some are fat, some medium, and some thin. So I decided to drill them to fit. I put paper tape on the base (so I could mark on it) and measured out the centerpoints. Then to be absolutely sure the shelf slots would match the base holes, I put the boards edge to edge and used a square to mark the shelf slots.

I drilled the holes in the base. The forstner bits are great for large flat holes. It looked great! Then I drilled half-holes in the upper shelf.

I was very careful about that. I used a sacrificial board underneath (because they were through-holes) to prevent tearout. I drilled a test hole in a piece of scrap board. I got some tearout anyway. Well that's the bottom side, so I decided to live with it.

That's part of the *#>&@*< feeling. Because of the way I transferred the base centerpoints to the shelf, the bottom of the shelf as I drilled it would actually be the top side when assembled!

So, when I put the cleancut side of the shelf "up", this is what I saw.

When I switched it so the holes matched up, the tearout side was "up".

And then I noticed that one of the shelf holes was 1/4" offset!

ARGGGGH! I am NOT a happy camper right now. Luckily, I have another 4" board. I'll remake the shelf tomorrow. This time, I'll know to put the shelf board ON TOP OF the base, not NEXT TO it when I transfer the centerpoints...

Sunday, August 30, 2009

Fishing Rod Rack Project, Part 2

OK! The base glued together well and only needed a little scraping on the edges for minor glue squeezeout. I used a finishing sander for good measure.

The first thing to do today was to make the cross boards EXACTLY the same lengths. I trimmed one end of the base board (F) on the table saw, then cut it 46". I used that to mark the lengths of boards A, B, and E. I tried to figure out a way to set up a "stop" on the miter gauge, but the fence can only get 30" from the table saw blade and the miter gauge isn't long enough on the other side of the blade to set up one there.

I could have set up a stop on the radial arm saw bench, but it seems to be about 1/4 degree out of square and I can't seem to adjust it any better than that. Oh well, it is good for rough deck and fence work, if not for cabinetry.

So I trimmed the pieces to size as best I could. When I stacked them all together even at one end, they were within 1/64" at the other. I clamped the stack together and power sanded the difference smooth. They ended up perfect.

I trimmed the sides (D) to 33" and am ready to start putting the frame together (Boards A, B, D and D).

I also need to rout slots into board E and drill 1 1/4" holes with forstner bits 1" deep into board F. But it is time for dinner, and I like to have wine with dinner, so there won't be any more woodworking tonight!

The first thing to do today was to make the cross boards EXACTLY the same lengths. I trimmed one end of the base board (F) on the table saw, then cut it 46". I used that to mark the lengths of boards A, B, and E. I tried to figure out a way to set up a "stop" on the miter gauge, but the fence can only get 30" from the table saw blade and the miter gauge isn't long enough on the other side of the blade to set up one there.

I could have set up a stop on the radial arm saw bench, but it seems to be about 1/4 degree out of square and I can't seem to adjust it any better than that. Oh well, it is good for rough deck and fence work, if not for cabinetry.

So I trimmed the pieces to size as best I could. When I stacked them all together even at one end, they were within 1/64" at the other. I clamped the stack together and power sanded the difference smooth. They ended up perfect.

I trimmed the sides (D) to 33" and am ready to start putting the frame together (Boards A, B, D and D).

I also need to rout slots into board E and drill 1 1/4" holes with forstner bits 1" deep into board F. But it is time for dinner, and I like to have wine with dinner, so there won't be any more woodworking tonight!

Saturday, August 29, 2009

Fishing Rod Rack Project

FISHING ROD RACK

After having my fishing rods leaning against the garage wall for years, and having them all fall over whenever one got bumped, I decided I needed a rod rack. I looked at some for purchase but I didn't like any of them (all were either too cute, way too fancy, or held too few rods). Besides, why buy when you can build?

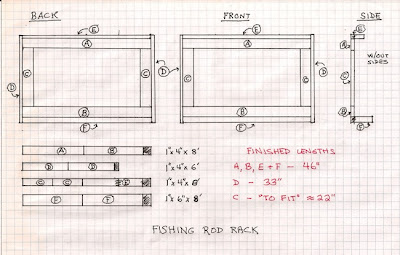

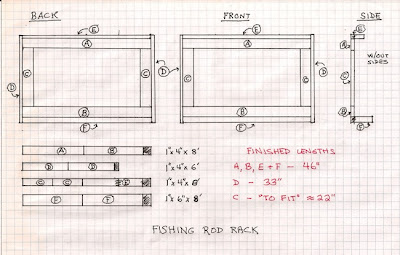

So I sat down to design one. My 1st design had all the rods standing straight up through holes, but I realized they would all lean slightly in different angles. Functional, but aesthetically unpleasing...

So I tried again. This time, I decided to have them set in holes in the base and lean into slots in a higher shelf. That would have them all at a consistent angle. It took a while to find a height for the upper shelf where no ferrules would be in the way. And I reworked the design a couple of times to make sure the construction was solid.

So here is what I came up with (double-click the picture for enlargement):

I was surprised to notice that the front and back views are identical. I was also trying to use boards I already had, so the 2" base is actually two 1" boards glued together.

So I laid out my boards:

Most of the boards needed to be cut approximately in half. That was too long for my table saw (because of the Incra Fence), but my old radial saw has plenty of room. Since there is at least 2" of waste on each board, I could cut them all oversize (the radial arm saw does not seem to cut as squarely as the table saw).

Boards A, B, E, and F have to all be exactly the same length, so I glued up the 2 boards for F (the base) and left it until tomorrow.

You can never have too many clamps. LOL!

After having my fishing rods leaning against the garage wall for years, and having them all fall over whenever one got bumped, I decided I needed a rod rack. I looked at some for purchase but I didn't like any of them (all were either too cute, way too fancy, or held too few rods). Besides, why buy when you can build?

So I sat down to design one. My 1st design had all the rods standing straight up through holes, but I realized they would all lean slightly in different angles. Functional, but aesthetically unpleasing...

So I tried again. This time, I decided to have them set in holes in the base and lean into slots in a higher shelf. That would have them all at a consistent angle. It took a while to find a height for the upper shelf where no ferrules would be in the way. And I reworked the design a couple of times to make sure the construction was solid.

So here is what I came up with (double-click the picture for enlargement):

I was surprised to notice that the front and back views are identical. I was also trying to use boards I already had, so the 2" base is actually two 1" boards glued together.

So I laid out my boards:

Most of the boards needed to be cut approximately in half. That was too long for my table saw (because of the Incra Fence), but my old radial saw has plenty of room. Since there is at least 2" of waste on each board, I could cut them all oversize (the radial arm saw does not seem to cut as squarely as the table saw).

Boards A, B, E, and F have to all be exactly the same length, so I glued up the 2 boards for F (the base) and left it until tomorrow.

You can never have too many clamps. LOL!

Subscribe to:

Posts (Atom)

Adventures In Driving

Last month, my cable box partially died, so they sent a replacement. But they wanted the old one back anyway. The store in town only hand...

-

I think I have it figured out now. I needed basic frame strength (cubes) plus top support (arches with a ridgepole) for shedding rain and s...

-

I like to plant Pansies in the Fall. I replace the dead Tomatos and deck pot flowers with them most years. Best deal I found was 12-packs ...